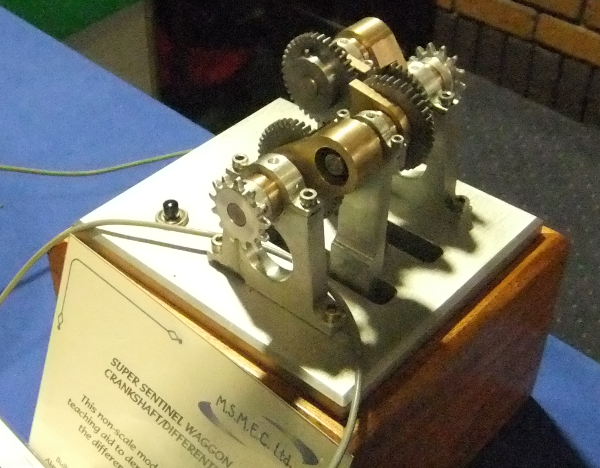

SUPER SENTINEL WAGGON CRANKSHAFT/DIFFERENTIAL.

This non-scale model has been built as a teaching aid to demonstrate the operation of the differential within the crankshaft.

Built by Alan Reynolds.

BURRELL AGRICULTURAL TRACTION ENGINE.

4" : 1 ft. Scale.

Front wheels for this engine: the model is being built from the kits supplied by “Steam Traction World”.

Being built by Ian Grantham.

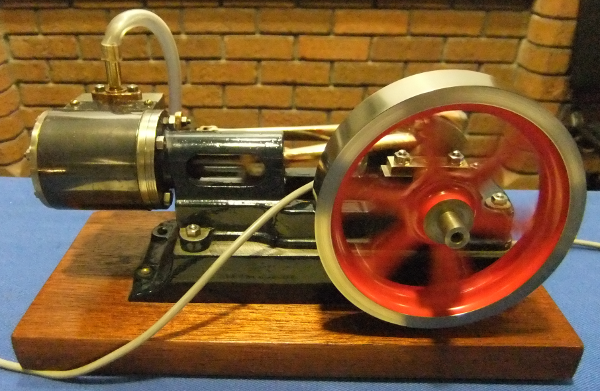

HORIZONTAL STEAM ENGINE

Stuart Turner No. 8 Bore 1", Stroke 1"

Built from castings on a 4½” lathe.

Built by CM.

A COLLECTION OF ELEVEN I.C. ENGINES.

All these engines were designed by Edgar. T. Westbury.

Exhibited by Tony Grantham.

EDGAR. T. WESTBURY 1896 – 1970

E.T.Westbury contributed to “Model Engineer” magazine over a long period of time, and on a wide variety of subjects including marine and stationary steam engines and workshop equipment.

However, he is best remembered for his many internal combustion engine designs intended for a wide range of uses.

Most of the engines shown here were made by the exhibitor, and represent engines for marine, aero and tethered car use. Other designs by ETW were intended for stationaryuse, rail traction and even pedal cycle assistance.

No. 1: “KIWI MkII”. 15cc OHV water-cooled petrol engine, complete with home-built magneto. No castingswere used – all components cut from the solid.

No. 2: “ATOM V”. 30cc “racing” engine for tethered hydroplane racing. This engine still needs a few details to complete.

No. 3: “DOLPHIN”. 10cc OHV. This general purpose engine was purchased complete, but it is being re-made. Most of the internals will be replaced. The castings have been re-machined to correct errors, and, so far, 10 holes have had to be plugged, re-drilled & re-tapped.

No. 4: “CADET”. 5cc spark ignition. Recently completed using crankcase and other castings from the long-defunct Craftsmanship Models concern. The front and rear housings were cast in home-made dies.

Nos. 5 & 6: “ATOM MINOR”. 6cc spark ignition. No.6 is a rare example of a commercially made Westbury engine, and is noteworthy for having FRONT disc induction, whilst No.5 is the more usual rear disc type and, like the “KIWI”, was built when the exhibitor was an apprentice.

No. 7: “ENSIGN”. 10cc. This was intended for tethered car use and the design was first published in “Model Car News”. This version was made from commercial castings, and has a H.T. steel liner cast in the alloy cylinder, rather than a one piece cast iron cylinder.

No. 8: “CRAFTSMAN TWIN”. 10cc flat twin. These castings were produced by Craftsmanship Models Ltd., before the design was published in ME. By then, several modifications had been made to the dies. The unmachined castings were purchased at a steam rally in 1993.

No. 9: Two “CADETS” fitted together make a “CHERUB” 10cc flat twin. This example was made up in the same way as No 4. The centre main bearing contains a 2-way valve feeding front and rear crankcases alternately.

No. 10: “LADYBIRD”. 2.5cc twin. ETW’s only diesel (compression ignition) design: all made from the solid – never again! But it does sound wonderful when running!

No. 11: “KESTREL”. 5cc spark ignition. A pre-war design which was used in boats, aircraft and cars. A complete, but poorly made engine was purchased from an antique shop in 1996. Only the head, crankcase and tank castings now remain in this reconstruction.

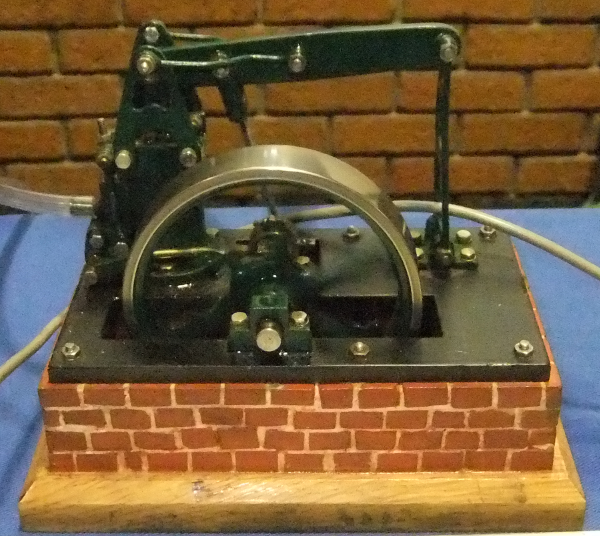

“GRASSHOPPER” BEAM ENGINE

This model is built to a design published In Model Engineer magazine.

Only one casting was used, all other components being machined from bar stock.

Built by Jon Lacey

LMS 4F 0 – 6 – 0 TENDER LOCOMOTIVE “PROJECT”

Gauge 1, (1¾” or 45mm).

Methylated spirit fired, working pressure 50 p.s.i.

This live steam locomotive has been built to the well known Gauge One Model Railway Association “Project” design – particularly aimed at beginners, or those with limited workshop facilities. Since being exhibited last year, the boiler has been completed and steamed, although some fine tuning is still needed. A start has now been made on the boiler and firebox cladding. It is a first attempt at building a live steam model from scratch.

Built by Ricky Smith.

LNER J38 0 – 6 – 0 TENDER LOCOMOTIVE

Gauge 1, (1¾” or 45mm).

This live steam locomotive has been built from a Barrett Steam Locomotives kit.

A fair range of kits and ready-to-run locos are available in this gauge, and this particular one is good for beginners since it mainly involves putting together a kit of ready-made parts.

Being built by Ricky Smith.

JAMES BOOTH RECTOLINEAR STEAM ENGINE

Patented 1843

The reciprocating motion of the piston drives one end of the link, the other end of which is connected to the horizontal crosshead. The combined motion pulls the centre of the link around a circular path, and the crank produces the rotary motion.

There is no need for a connecting rod, which reduces the height of the engine.

It was designed for use in Paddle Steamers, or machinery on land.

Built by Alan Temple.

1903 De Dion Motor Car

Scale: 4" : 1 ft. ( 1/3)

Made from his "hoard of useful junk" and involving the skills of scrap metal scrounger, foundryman, metal machinist, blacksmith, sheetmetal worker, welder and wheelwright so far!

Under the bonnet

Engine close up.

A view of the combined gearbox and differential.

Under Construction by Colin Hawes.

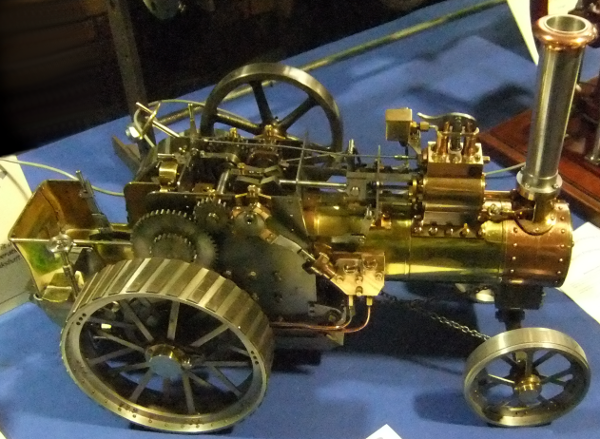

“MINI” TRACTION ENGINE. Scale 1" : 1 ft.

To the design by L.C.mason published in Model Engineer Magazine.Built over a five year period, all on a 4½” lathe.

Built by CM.

“COFFEE CUP” HOT AIR ENGINE

Built to a design by Jan Ridders, whilst summoning up the courage to paint a recently completed loco model.

Built by CM.

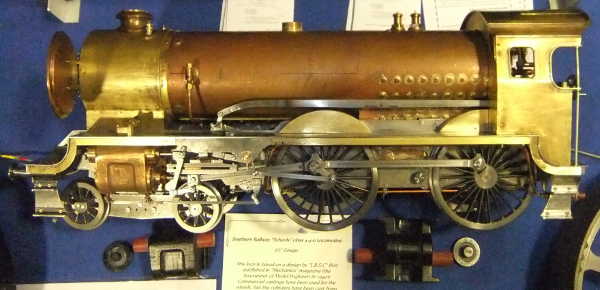

Southern Railway “Schools” class 4-4-0 Locomotive.

3½” Gauge.

This loco is based on a design by “L.B.S.C” first published in “Mechanics” magazine (the forerunner of Model Engineer) in 1940's. Commercial castings have been used for the wheels, but the cylinders have been cast from the builder’s home-made patterns. The boiler was made at home, using Propane heating. The loco is about 80% complete, but the tender has not been started - yet.

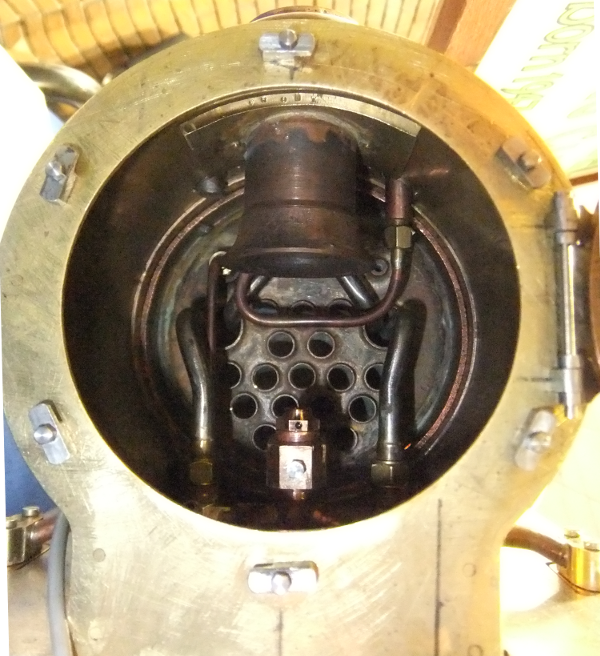

Smoke box

Fire box and controls.

Being built by Dave White.

“SPEEDY” LOCOMOTIVE 5" Gauge.

Running Chassis in bare metal.

Being built by Jon Lacey.

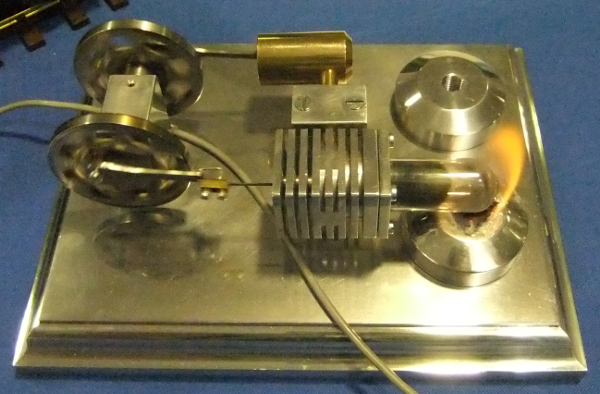

STIRLING “HOT AIR” ENGINE

This engine has a regenerator as part of the displacer piston, and is built from a kit by Forest Classics.

The builder has designed and constructed a new base with integral methylated spirit burner and separate filler made from Aluminium plate.

Built by Benedict White